Why is polishing important?

stone polishing is one of the most important steps in stone processing. This stage is very important in that it determines the transparency of the stone. Most of those who are somehow related to stone work or those who are consumers of building stone know that the transparency and shine of the stone will be very effective in selling it. All the manufacturing plants try to make the highest level of quality on the stone so that the customer is encouraged to buy it.

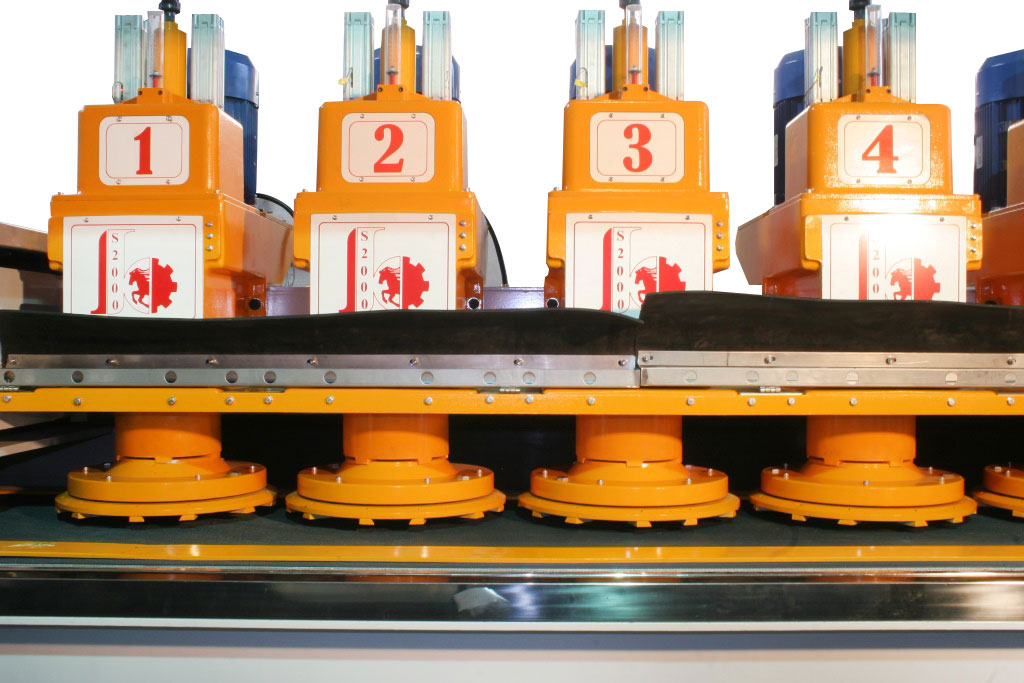

If the stone enters the sanding machine after the cutting stage, the polishing process starts. Sanding or polishing in different stones has different methods and recipes. Sanding in granite and porcelain is completely the same, and the stone is polished and polished only with the bite of designed sanding boards

What is the purpose of stone polishing?

stone polishing As we said, building stones are sanded in different conditions. Sandblasting is done using sandblasting machines. In this device, sub operation is performed using a part called bite

The morsel itself has different types, each of which is used for specific purposes. Among the reasons for implementing SAB, the following can be mentioned:

Exfoliating the surface of the stone and removing the stains and dirt created۱۲

Increasing the luster of the stone and increasing its beauty.

Leveling the stones and creating a smooth surface.

Filling the holes and helping the uniformity of the stone surface.

Removing construction materials such as cement, paint, glue, etc., which are stuck on the stone and

Sub and polish in each stone depends on the material, texture and type of that stone. If the stone is soft like marble or marble or hard like granite, their polishing will be different, and for each of them, special abrasives are used for subbing and polishing.

“Click to view and buy all kinds of products of Karooghli Machinery Company“

Important points about

The sanding machine sands the surface of the stone well with the appropriate speed of the bites and the uniform distribution of pressure on the surface of the stone.

At this stage of stone processing, it is important to observe the following points.

۱ – The level of the stone

۲- Not having the screen of the device

۳- The high quality of the bites

When sanding, raw materials such as magnesium mortar and resin mortar are used.

The bits of sub machines have special numbers, the higher the number, the more polished the surface of stone grindingthe stone. For subsang, you have to take these bites step by step from the bottom numbers to the top

Grinding all kinds of stones

Marble stone

Marble stone sometimes has small surface cracks or small holes and therefore it must be resinated. This material has different fillers that will be mentioned.

At the discretion of the technical manager of the marble and marble factory, it is prepared for sanding with a special filler and protector, and after sanding, it is cut to the desired dimensions.

Travertine

Some factories pass the travertine stone under the saber machine after cutting it once and sand it with low-grade bits and polishers. After that, the process of drying the stone is done. And the stone is prepared for the resin stage. After the resin is done and the travertine holes are completely covered. The stone takes some time to dry. And then it is prepared for the main grinding stage. At this stage, the surface of the stone is polished with higher grade polishers, the surface of the travertine stone will be completely polished.

Completion of the operation

Most of the consumers expect good gloss and sub from a product, while such a situation is usually not met and the final result does not include such a result, because often the work of filling the holes with resin is not done correctly in Iran, and basically if the surface is filled With the resin, it is not shiny, we have not reached our goal. Saab stone is done with the Saab machine after the filling stage. The Saab machine depends on the type of stone and whether it is hard or soft. The number of heads of the Saab machine in granite is between sixteen to There are twenty-two heads and in marble there are between ten and sixteen heads, which is known as sub-sixteen heads or..

Summary

Above, we mentioned the methods of stone cutting and stated that each cutting method is suitable for which stone. One of the scales that is used in stone cutting, don’t forget that you can use this service to repair the appearance of the stone in cases such as broken and cracked stone

Purchase and price of stone polishing machine

Karakli Machinery Manufacturing, manufacturing of stone cutting machines and setting up a slab and tile line of Asal Sanat Sepahan Company in 1330 under the name of Karakli Machinery Manufacturing with the aim of providing automotive and mill services.

Car body repair was established in Isfahan province. Dear ones, you can contact us to know the price and buy the products.

Contacts

Address :

Isfahan, Imam Khomeini St., Zarin St

contact numbers :

افزودن دیدگاه